It has become increasingly common in recent years for filling station operators to rely on remote wetstock monitoring to detect possible leaks in their system. Tank and pump gauges are monitored remotely with sophisticated trend analysis used to detect abnormal behaviour. These systems can be very good, but they aren’t infallible.

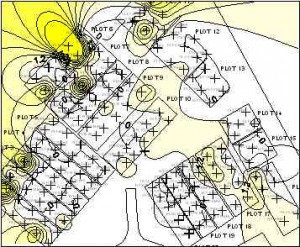

Last year Subadra were retained to clean up contamination resulting from a leak at a filling station. Our treatment was completed successfully over the winter months and by mid-summer we had started post-remedial monitoring, with groundwater samples taken at monthly intervals from monitoring wells we had installed at the site.

Our consultants noticed some anomalous results appearing and, in best CSI fashion, our laboratory carried out a programme of forensic analysis. This was able to determine the ‘age’ of the contamination we were finding, telling us how long the leaked fuel had been in the ground. This confirmed that the wells were being contaminated from a new source.

The site’s real-time remote wetstock monitoring was checked but didn’t show a leak at the site. However, on our advice, the site operator had the tanks and lines pressure tested and this identified a steady slow leak from one of the pumps. Repairs were carried out limiting the volume of fuel lost into the ground.

The moral of the tale? Well, remote wetstiock monitoring is very good and we would certainly recommend it. But it’s not infallible. In those cases, forensic analysis can help identify leaks that wetstock monitoing misses.

If you’d like to know more about our forensic analysis service or any of the other services offered by our UKAS/MCerts accredited laboratory please contact Kate Clark.